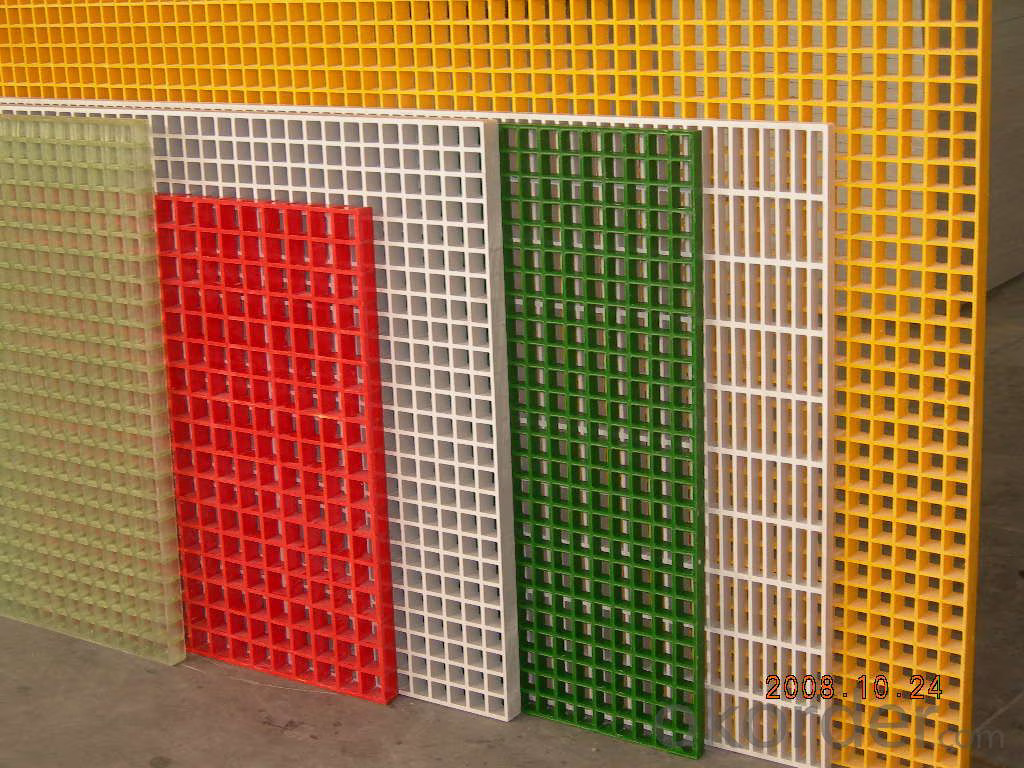

FRP Gratings

FRP Moulded Grating

FRP (Fiberglass Reinforced Plastic) Moulded Grating is a durable and versatile flooring solution made from fiberglass reinforced polymer. This type of grating is designed to provide a lightweight, corrosion-resistant, and slip-resistant surface, making it ideal for a variety of industrial and commercial applications.

Uses

Commonly used in factories, processing plants, and manufacturing facilities for walkways and work platforms.

Ideal for environments where chemical spills may occur, as it is resistant to corrosion and degradation from various chemicals.

Utilized in sewage treatment and water purification facilities due to its resistance to moisture and chemicals.

Suitable for use on docks, piers, and ships where exposure to saltwater is a concern.

Advantages

FRP moulded grating is highly resistant to rust, corrosion, and chemical attack, ensuring longevity even in harsh environments.

Compared to metal alternatives, FRP is lighter, making it easier to handle and install, which reduces labor costs.

Designed with a slip-resistant surface to enhance safety in wet or oily conditions.

Requires minimal upkeep and is easy to clean, making it a cost-effective flooring solution.

Functionality

FRP Moulded Grating is engineered for strength and safety, providing a durable walking surface that can support heavy loads while allowing for drainage and ventilation. The open grid design promotes airflow and reduces the accumulation of debris and liquids, enhancing safety in industrial environments. Additionally, FRP grating is non-conductive, making it a safe choice for electrical installations. Overall, FRP Moulded Grating is an excellent solution for facilities requiring a robust and reliable flooring option that can withstand demanding conditions.

FRP Drainage Cover

FRP (Fiberglass Reinforced Plastic) Drainage Covers are specially designed to provide secure, durable, and lightweight solutions for covering drainage systems in various applications. Made from high-quality FRP materials, these covers are engineered to withstand harsh environmental conditions while offering excellent corrosion resistance and long-lasting performance.

Uses

Utilized in streets, parking lots, and sidewalks to cover drainage channels and prevent debris from clogging the drainage system.

Protects drainage systems in factories, warehouses, and processing plants, ensuring efficient water management and safety.

Covers for drains in sewage treatment facilities to facilitate effective waste management and prevent accidents.

Used in shopping centers, hotels, and office complexes to manage rainwater runoff and enhance aesthetic appeal.

Advantages

FRP is inherently resistant to chemicals, rust, and corrosion, making these covers ideal for various environmental conditions.

Easy to handle and install compared to traditional metal or concrete covers, reducing labor costs and installation time.

Highly resistant to impact and abrasion, ensuring long-term functionality and safety in high-traffic areas.

Provides electrical insulation, making it safe for use in electrical installations and reducing the risk of electrical hazards.

Functionality

FRP Drainage Covers are designed to fit securely over drainage systems, providing a protective barrier while allowing for efficient water flow. The lightweight yet robust design makes them easy to install and maintain. The covers often feature non-slip surfaces to enhance safety, particularly in wet or slippery conditions. Their corrosion-resistant properties ensure that they can withstand exposure to harsh weather and chemicals without deteriorating. Overall, FRP Drainage Covers offer a reliable, low-maintenance solution for effective drainage management in diverse applications.

FRP Grating

FRP (Fiberglass Reinforced Plastic) Grating is a high-performance flooring solution made from a composite of fiberglass and resin. It is designed for use in various industrial, commercial, and residential applications, providing a lightweight, durable, and corrosion-resistant alternative to traditional metal or wood grating.

Uses

Commonly used in factories, processing plants, and manufacturing facilities for walkways, work platforms, and access areas.

Ideal for environments where chemical spills may occur, offering protection against corrosive substances.

Utilized in sewage treatment plants and water purification facilities, providing a safe and durable flooring option.

Suitable for docks, piers, and ships, where exposure to saltwater and harsh weather is a concern.

Advantages

FRP grating is highly resistant to rust, corrosion, and chemical attack, ensuring longevity even in harsh environments.

Compared to metal grating, FRP is lighter, making it easier to handle and install, which can reduce labor costs.

Designed with a slip-resistant surface to enhance safety, especially in wet or oily conditions.

Requires minimal upkeep and is easy to clean, making it a cost-effective flooring solution.

Functionality

FRP Grating is engineered to provide a strong and safe walking surface that can support heavy loads while allowing for drainage and ventilation. The open grid design promotes airflow and reduces the accumulation of debris and liquids, enhancing safety in industrial environments. Additionally, FRP grating is non-conductive, making it a safe choice for electrical installations. With its combination of strength, safety, and resistance to environmental factors, FRP Grating is an excellent flooring solution for diverse applications across various industries.

Connect with Madar Technoplast : Solutions Tailored to Your Needs

Have a question or need assistance with FRP solutions? Our expert team is here to provide the support and guidance you need for your next project.