FRP Tanks

FRP Storage Tank

Fiberglass Reinforced Plastic (FRP) Storage Tanks are highly durable, corrosion-resistant tanks designed to store a range of chemicals, water, and other liquids in industrial, agricultural, and commercial applications.

Uses

Ideal for storing corrosive chemicals like acids, alkalis, and solvents.

Effective in wastewater and potable water treatment plants.

Suitable for food-grade liquid storage, complying with hygiene standards.

Useful for storing fertilizers, pesticides, and other agricultural products.

Advantages

Unlike metals, FRP tanks resist corrosion from aggressive chemicals, prolonging lifespan.

Easier to transport and install than conventional metal tanks.

Requires minimal maintenance, lowering operational costs.

Available in various shapes, sizes, and configurations to meet specific requirements.

Functionality

FRP Storage Tanks are engineered with reinforced fiberglass and resin, ensuring a leak-proof and robust structure. This construction allows them to withstand harsh conditions and chemicals, providing a reliable storage solution across industries.

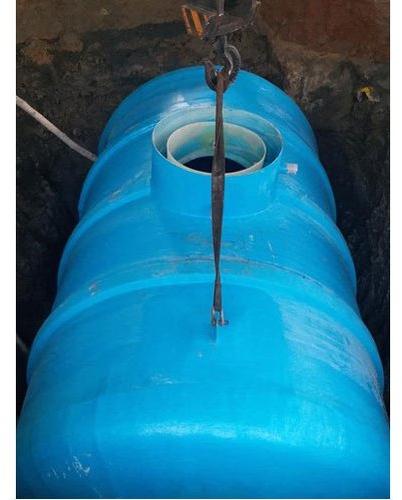

FRP Petrochemical Underground Tank

FRP Petrochemical Underground Tanks are specialized storage solutions designed to store petroleum products, petrochemicals, and other hazardous substances underground. Built from Fiberglass Reinforced Plastic (FRP), these tanks are ideal for applications where resistance to corrosion and environmental protection are crucial.

Uses

Suitable for storing gasoline, diesel, and other fuels in gas stations.

Used for storing petrochemical substances in refineries and industrial plants.

Provides safe storage for various hazardous liquids underground, minimizing surface risks.

Often incorporated in fire safety infrastructure to store flammable liquids underground securely.

Advantages

Highly resistant to corrosion from both stored materials and soil conditions, which enhances the tank's durability.

Engineered with a double-wall design that often includes a leak detection system for added safety.

Designed to prevent contamination of soil and groundwater, crucial for environmentally sensitive applications.

Lighter than steel tanks yet durable, making installation easier and reducing transportation costs.

Functionality

The FRP Petrochemical Underground Tank combines layers of reinforced fiberglass with high-quality resins, creating a robust structure that resists cracking, leaks, and corrosion. These tanks are designed for underground use, with features like leak detection and double-walled construction to provide safe and secure storage of petrochemical substances.

PP FRP / PVC FRP / GRP Storage Tank

PP FRP (Polypropylene FRP), PVC FRP (Polyvinyl Chloride FRP), and GRP (Glass Reinforced Plastic) Storage Tanks are versatile storage solutions designed to store corrosive chemicals, water, and various industrial liquids. These tanks combine the corrosion-resistant properties of thermoplastics (PP and PVC) with the strength of fiberglass, making them highly reliable for diverse applications across industries.

Uses

Effective for storing acids, alkalis, and other corrosive chemicals.

Used in storing both potable and wastewater in treatment facilities.

Safe for storing food-grade materials and liquids.

Used for safely storing raw materials, reagents, and solvents.

Ideal for handling and storing chemicals used in the plating process.

Advantages

Resistant to chemical reactions, ensuring longevity and minimal contamination risks.

Strong yet lightweight due to reinforced fiberglass construction.

Excellent thermal stability, suitable for temperature-sensitive liquids.

Can be manufactured in various shapes, sizes, and thicknesses to suit specific storage needs.

Functionality

These tanks are built with an inner lining of PP, PVC, or GRP, which provides excellent resistance to chemicals, and an outer structure of FRP for added strength and durability. The combination of materials ensures that the tanks withstand harsh industrial environments, resist leaks, and provide a secure storage solution for both corrosive and non-corrosive liquids. The design also allows these tanks to be customized with features like heating coils or fittings, tailored to specific operational requirements.

FRP (GRP) Rectangular Storage Tank

FRP (Fiberglass Reinforced Plastic) or GRP (Glass Reinforced Plastic) Rectangular Storage Tanks are specialized tanks shaped to optimize space in storage and process areas. These tanks offer corrosion resistance, durability, and are suitable for storing a variety of chemicals, water, and wastewater in confined spaces.

Uses

Ideal for storing acids, alkalis, and other aggressive chemicals in compact industrial setups.

Used for storing wastewater or processed water in treatment plants.

Suitable for storing food-grade liquids in rectangular spaces for efficient use.

Used in electroplating tanks for chemical immersion and metal processing.

Advantages

The rectangular shape allows maximum storage capacity in limited spaces.

Excellent resistance to corrosive chemicals and extreme conditions, ensuring longevity.

Strong and lightweight due to the GRP construction, which makes handling and installation easier.

Durable and requires less frequent maintenance, reducing overall operational costs.

Functionality

FRP (GRP) Rectangular Storage Tanks are constructed using layers of glass fiber and resins, making them durable, leak-proof, and able to withstand various chemical reactions. These tanks provide a robust solution for applications requiring efficient space use and high corrosion resistance. The structural design can be customized to include additional features like compartments, dividers, and specialized inlets or outlets, catering to industry-specific needs.

FRP Chemical Storage Tanks

FRP (Fiberglass Reinforced Plastic) Chemical Storage Tanks are designed to store corrosive and hazardous chemicals safely. Known for their durability and resistance to chemical reactions, these tanks are widely used across industries where high resistance to corrosion and environmental factors is essential.

Uses

Ideal for storing acids, alkalis, solvents, and other corrosive chemicals.

Used for handling and treating chemicals in wastewater management facilities.

Stores chemicals necessary for various processes in power plants.

Suitable for food-grade chemicals and additives, meeting industry safety standards.

Advantages

Highly resistant to chemical reactions, preventing corrosion and extending tank lifespan.

Designed to be leak-proof, offering a safe solution for hazardous chemical storage.

Robust construction makes them capable of withstanding extreme temperatures and pressure.

Easier to transport and install than steel tanks, reducing handling costs.

Functionality

Constructed with layers of reinforced fiberglass and chemically resistant resins, FRP Chemical Storage Tanks provide a sturdy, non-corrosive storage environment for hazardous materials. These tanks are designed with safety features like leak detection systems and double-wall configurations to ensure safe containment. Their lightweight yet strong structure allows easy installation in both above-ground and underground applications, providing a reliable storage solution for industries dealing with aggressive chemicals.

FRP Underground Water Tanks

FRP (Fiberglass Reinforced Plastic) Underground Water Tanks are designed to store potable and non-potable water safely below ground. These tanks offer exceptional durability, corrosion resistance, and long-term reliability, making them an ideal choice for residential, commercial, and industrial water storage needs.

Uses

Safely stores drinking water for residential and commercial buildings.

Ideal for collecting and storing rainwater for irrigation or greywater systems.

Used as emergency water storage in fire safety applications.

Suitable for agricultural water storage, reducing dependency on groundwater sources.

Advantages

Resists soil chemicals and groundwater effects, preventing rust and decay.

Designed for durability, providing years of service with minimal maintenance.

Lighter than concrete, reducing transportation and installation costs.

Leak-proof construction prevents soil and water contamination, protecting the environment.

Functionality

FRP Underground Water Tanks are constructed with reinforced fiberglass layers and resin, creating a tough, leak-proof, and corrosion-resistant structure. These tanks are engineered to withstand underground pressure and soil movements, ensuring secure water storage below ground. With customizable options for size, capacity, and fittings, FRP Underground Water Tanks offer a safe and efficient water storage solution adaptable to diverse site requirements.

PP FRP Storage Tank

PP FRP (Polypropylene Fiberglass Reinforced Plastic) Storage Tanks are highly resistant to corrosion and chemical reactions, making them ideal for storing aggressive and corrosive chemicals. These tanks combine an inner lining of polypropylene with an outer layer of fiberglass, offering a durable, lightweight, and reliable solution for various industries.

Uses

Stores corrosive chemicals, acids, and alkalis safely.

Suitable for holding treated water, wastewater, and effluents.

Stores raw materials, reagents, and finished products.

Used for dyes and other reactive substances in textile manufacturing.

Advantages

PP lining ensures resistance to a wide range of chemicals, preventing degradation.

FRP exterior provides structural strength, protecting the tank from environmental wear and mechanical stress.

Non-corrosive materials reduce maintenance costs and extend tank lifespan.

Easier to transport and install compared to metal tanks.

Functionality

The PP FRP Storage Tank combines a chemically resistant polypropylene lining with a robust fiberglass-reinforced structure. This dual-layer construction provides a leak-proof, long-lasting, and safe storage solution for hazardous chemicals and sensitive materials. Ideal for both above-ground and underground installations, PP FRP Storage Tanks are customizable with optional features such as heating systems or insulation, tailored to specific operational requirements.

Connect with Madar Technoplast : Solutions Tailored to Your Needs

Have a question or need assistance with FRP solutions? Our expert team is here to provide the support and guidance you need for your next project.